hydraulic piston seal rubber wear ring

1. Suit for many kinds of seal form

2. Suit for many kinds of activity mode

3. Suit for many different sealing media

4. Simple design, compact structure, convenient assembly and disassembly

5. Small running friction

Good chemical stability, heat resistance, cold resistance, oil, water, steam, chemicals and other media; high mechanical strength, high pressure, abrasion resistance; low coefficient of friction, self-lubricating.

Working Condition:0~70Mpa

Speed:Maximum rotational speed up to0.5m/s Maximum reciprocating speed up to2.0m/s

Application Temperature:-55~260 ℃

Working medium:each kinds lubricating oil, liquid and gas

Materials: PTFE fluorine rubber/FKM/FKM/FPM, NBR/Nuna-N/nitrile rubber, EPDM, kalrez,HNBR,etc.

hydraulic piston seal rubber wear ring

rubber wear ring Package :

1)Knock-down package or as each customer required

2)pp bag inside , carton outside for rubber wear ring

rubber wear ring Application:

rubber wear ring Used for the manufacture of wear rings, guide ring, ring, sealing materials commonly used on machinery, widely metallurgy, petrochemical, engineering machinery, light industrial machinery and other fields for.

1.Western union,L/C,Paypal

2.30%TT in advance and balance 70% by copy of BL

rubber wear ring Samples Detail

1.Sampling base on customers’ requirements.

2.Cost depends on the design and if need make new mold.

3.Sample lead time is 7days

4.Mass production lead time is 10-15 days.

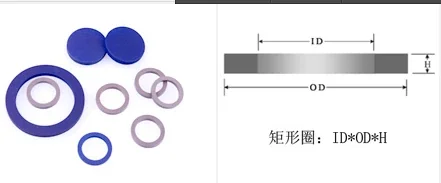

How to choose the rubber gasket?

The customer need to know rubber gasket Material, size, Hardness and also can provide the product drawing to supplier.

#1 size:

#2 Hardness:

Hardness is related with compressive directly. Normal conditions, hardness is higher, high voltage resisting is stronger.

| Hardness ( shores A) | 50±5 | 60±5 | 70±5 | 80±5 | 90±5 |

| Working pressure static seal/Mpa ≤ | 0.5 | 1 | 10 | 20 | 50 |

| Working pressure static seal Speed≤0.2m/s)/Mpa ≤ |

0.5 | 1 | 8 | 16 | 24 |

#3 Material:

According to working condition, choose suitable material.

We supply various types and sizes. The free sample is available .

If you are unsure what types is best for your application then you can contact us for consult.

If you can’t find what you are looking for, or require a special design in specific performance, please do not hesitate to

Company introduction(factory)

We offer all kinds of rubber molded parts in both small and large quantities. Like o-rings, rubber grommets, rubber bellows, rubber bumper, rubber plugs, gasket, etc. for usage in various industries. We not only supply the parts with standard specifications, but also produce the molded parts as per our customers’ drawings and samples.

Technology

Rubber gasket Process

Our Advantage

1.OEM:NOK,Parker from 2005

2.Certification:ISO9001,TS16949

3.Material:Imported raw material,assureed quality.(NBR-Japan,SIL-DowCorning, FKM-Dupont)

4.Mold:more than 20,000sets mold of o ring(include AS TM,JIS,GB etc)

5.Price:Processing in domestic factory keep competitive prices.

6.ERP System,comprehensive process control.

7.Free CNC machining center,strong ability of mold development and high speed of mold opening

Other product

If you have seals demand,so,just contact me,we can find out the right one for you.

1.Q: Are you a factory or trading company?

A: We have factory in Shijiazhuang, Hebei with export license. We have the most convenient transportation conditions.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Shijiazhuang City, Hebei Province, China. All our clients, from home or abroad, are warmly welcome to visit us!

3.Q: Can you do OEM?

A: Yes, we can do OEM products. It’s no problem.

4.Q: How can I get some samples?

A: 1.We are honored to offer you samples by express. Abroad clients are expected to pay for the freigh cost, the samples are free. For clients in China, we pay express fee.

2. Regarding the courier cost:

(1) you could arrange a RPI (remote pickup) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected;

(2) inform us your express freight collect account. Then you can pay the freight direct to your local carrier company;

(3) Transfer the cost to us in advance, the sample will be sent after receiving the payment

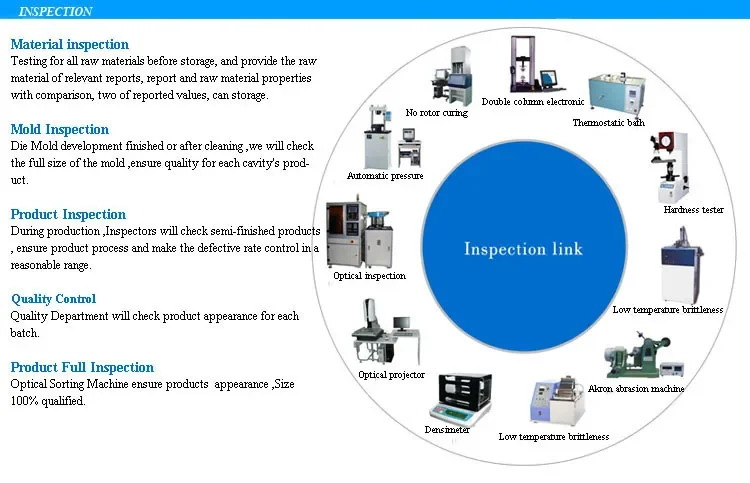

5.Q: How does your factory do regarding quality control?

1). All raw material we used are imported; Cooperation with Dupont, JSR and large raw material recip database, make our material properties are relatively stable, products’ quality be control.

2). Skilled workers care every details in handling producing and packing processes;

3). Quality Control Department specially responsible for quality checking in each process.

Thanks for you inquiry!

Send your Inquiry Details in the below for free samples, Click "send " Now !

-

Professional serviceLorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim a

Professional serviceLorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim a -

Patented design productsLorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim a

Patented design productsLorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim a -

Worldwide partnersLorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim a

Worldwide partnersLorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim a -

Factory OutletLorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim a

Factory OutletLorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim a